Latest News

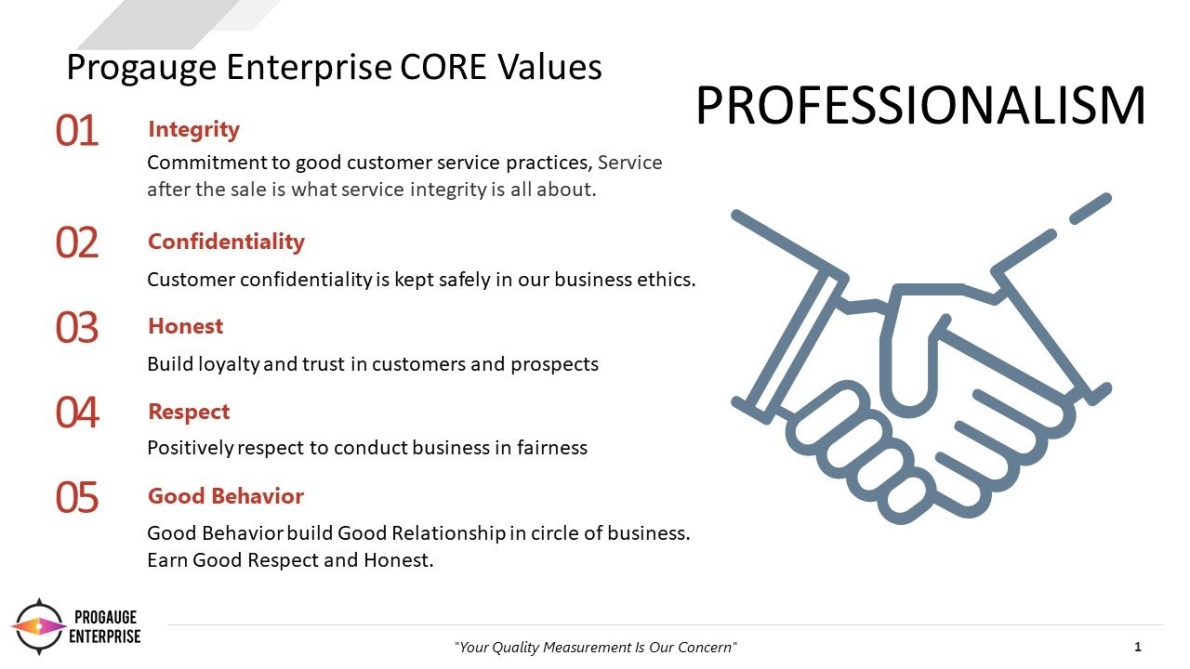

Learn about our company Core Values - Part 3

Mar 17, 2021

Our 3rd Core value is Professionalism.

There are many ways to gain professionalism in business circle. In ours we lay out 5 Important that needed and they are:

- Integrity

- Confidentiality

- Honest

- Respect

- Good Behaviour

Learn about our company Core Values - Part 2

Mar 16, 2021

Excellent is about confident to pursuit of highest quality of services Progauge Enterprise offer to customer and what we believe in what we are doing is to serve customer with On Time and persistent commitment in Every Time.

Learn about our company Core Values

Mar 15, 2021

Progauge Enterprise core value is built from the heart of our business and reflect our company is built upon and has being practised in our day-to-day business for more than 10 Years. These core value has set us to ensures all business conducted is on the same path, working towards a shared end goal throughout the operation of Progauge Enterprise.

Our Core Values are:

- Innovation – Thinking constantly improving our services to add value into customer and our work life output.

- Excellent – Deliver excellent of services on time every time.

- Professionalism – Being technically, competent and upholding 5 ethical standards (Integrity, Confidentiality, Honest, Respect and Good Behaviour) in our business

Today we share our 1st Core Values which is - Innovation.

We believe a company to thrive and survive in services market and to be outpace others, it is crucial to be continually innovating and improving in the process.

Progauge Enterprise has adapted Lean Management to innovate our way of doing business.

New revenue opportunities into specialize equipment calibration, optimising our existing channels by introducing reduction of calibration cost and boosts our calibration services to other sectors of industries to gain new experiences and know how knowledge work together with customer, these are our innovation in our business.

By Innovate our way of doing business, we add value not only to our work life, our customer is enjoying service value satisfaction increase as we grow in business.

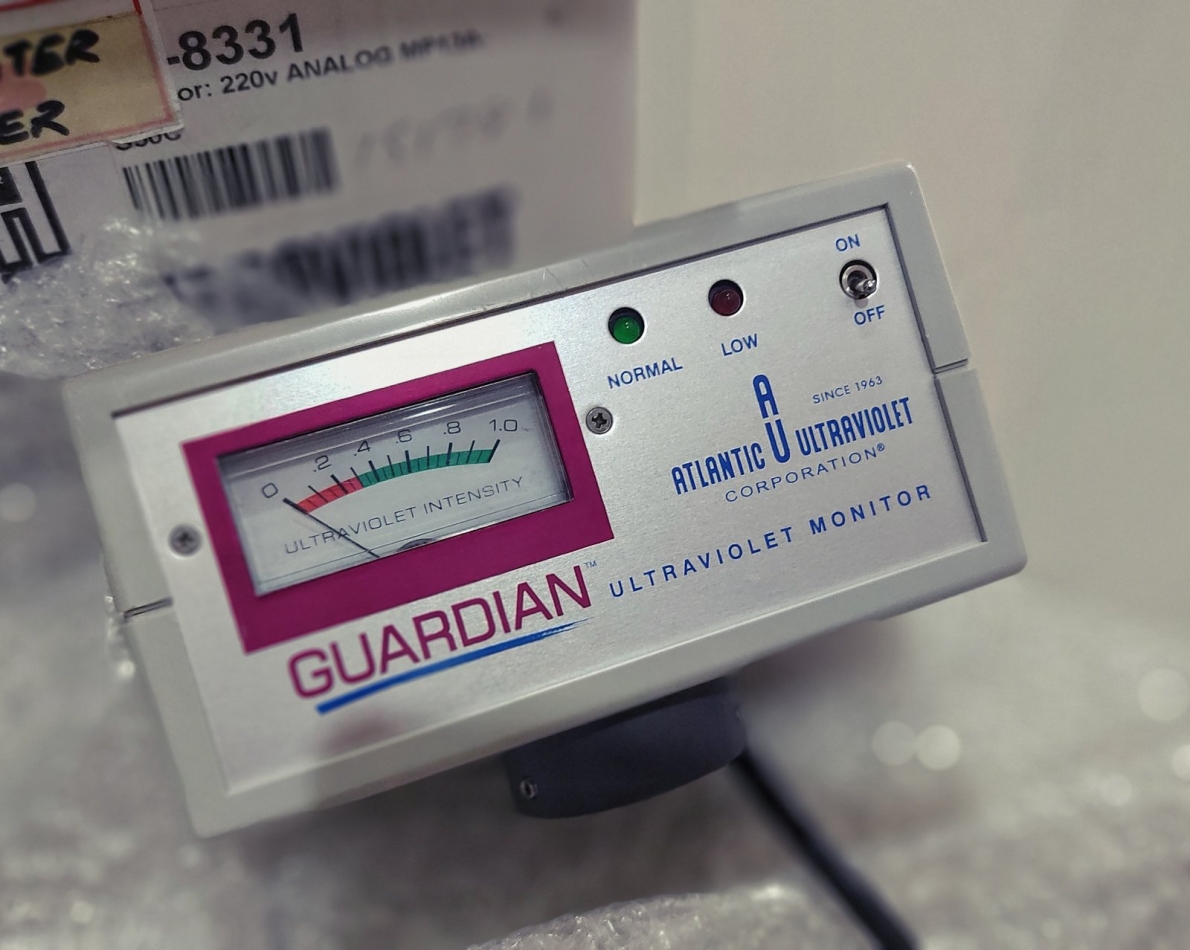

Ultraviolet Monitor - Guardian Calibration

Mar 11, 2021

Ultraviolet Monitor, model name: Guardian which is manufacturer by Atlantic Ultraviolet Corporation. This type of equipment is widely use in food processing industry. Its function is to measure the UV intensity presence in their process.

We did calibration to one of our customers that manufacture drinks and they use it to monitor UV in their systems.

We have performed calibration to all types of UV reading meter that widely use in Oil and Gas Industry and this is no foreign to us.

“Can Do” attitude by us, has definitely help and feel relieved.

Do contact us in 3 Ways method below for any calibration matters:

1. PM us here in Facebook Messenger

2. Whatapps us at +6011-6350 0321

3. Email your query to progauge@gmail.com

#calibrations

#calibrationequipment

#calibrationinstrument

#calibrationuvmeter

#CalibrationServices

#calibrationinmalaysia

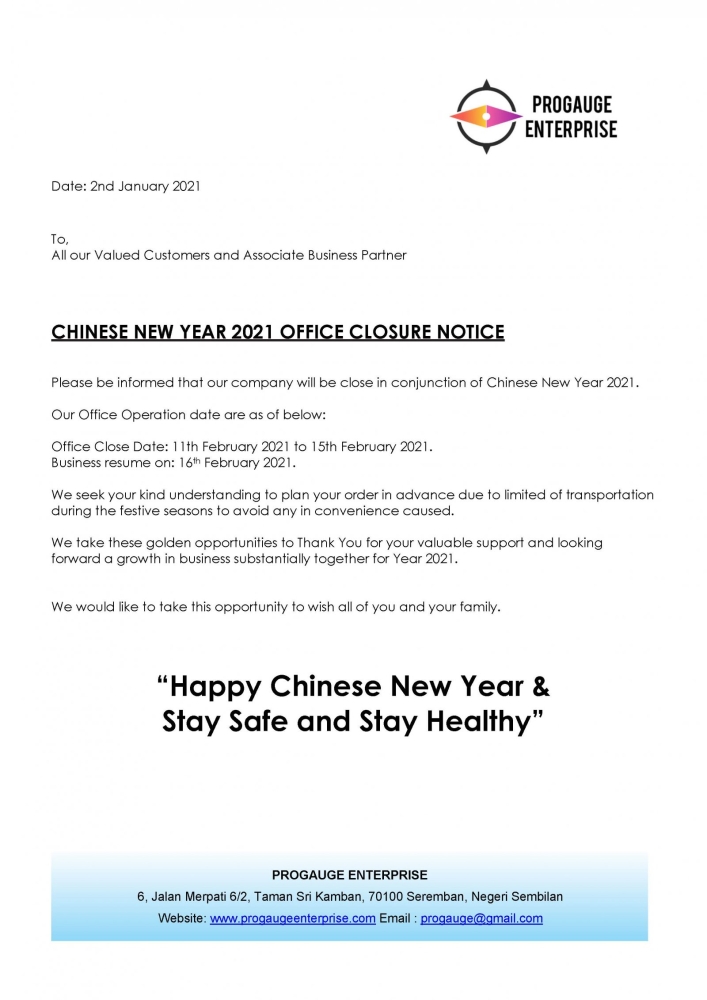

Announcement - CNY 2021

Feb 10, 2021

We will close our operation for CNY holiday from 11/2 until 15/2, our operation will resume 16/2 Tuesday.

We wish our Valuable Customer and Associate Business Partner, May Year of 2021 bring Health, Prosperous and Joyfulness to you and your family.

May We stay Strong and together grow prosper in Year 2021.

Happy Chinese New Year.

Progauge Enterprise - CNY 2021 Office Closure Notice

Feb 2, 2021

Our Office Operation date are as of below:

Office Close Date: 11th February 2021 to 15th February 2021.

Business resume on: 16th February 2021.

Click here for our Memo.

https://cdn1.npcdn.net/userfiles/22253/download/1612260514_8c3664a9c75c290c282042dfcd205a7e/Progauge_Enterprise_CNY_2021_Office_Closure_Letter.pdf

Wishing our Valued Customer and Business Associates

''Happy Chinese New Year & Stay Safe and Stay Healthy''

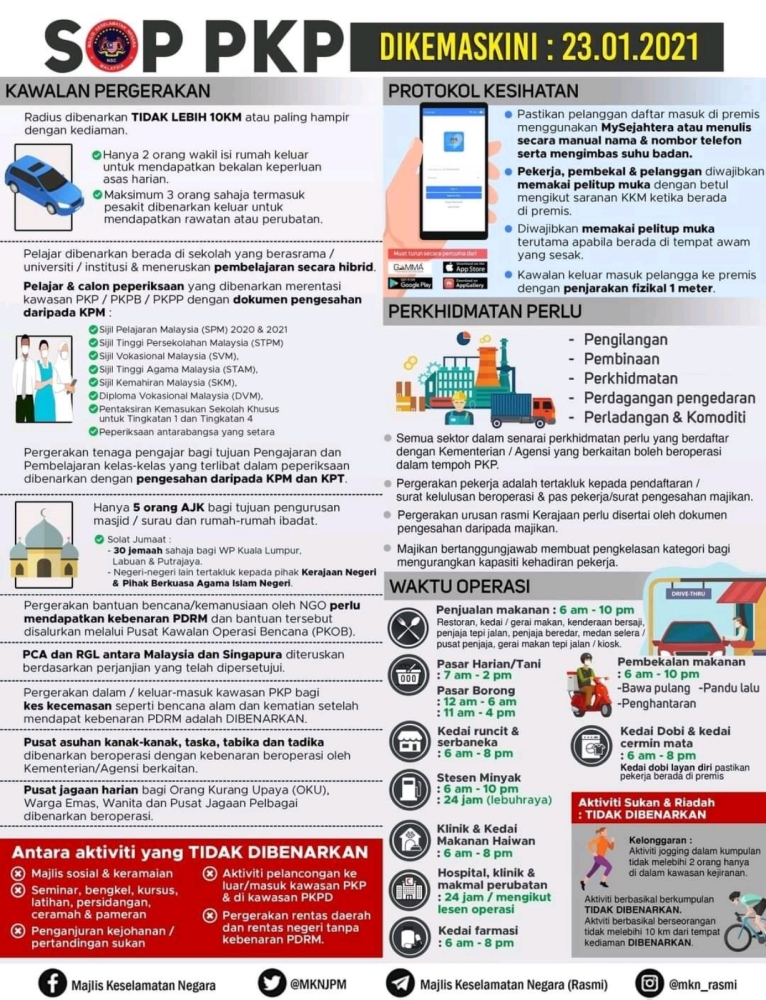

SOP for MCO (PKP) Area

Jan 24, 2021

Latest of the SOP up dated by our Kementerian Keselamatan Negara (KKN) till 23th January 2021.

Take Good Care, Stay Safe and Stay Healthy.

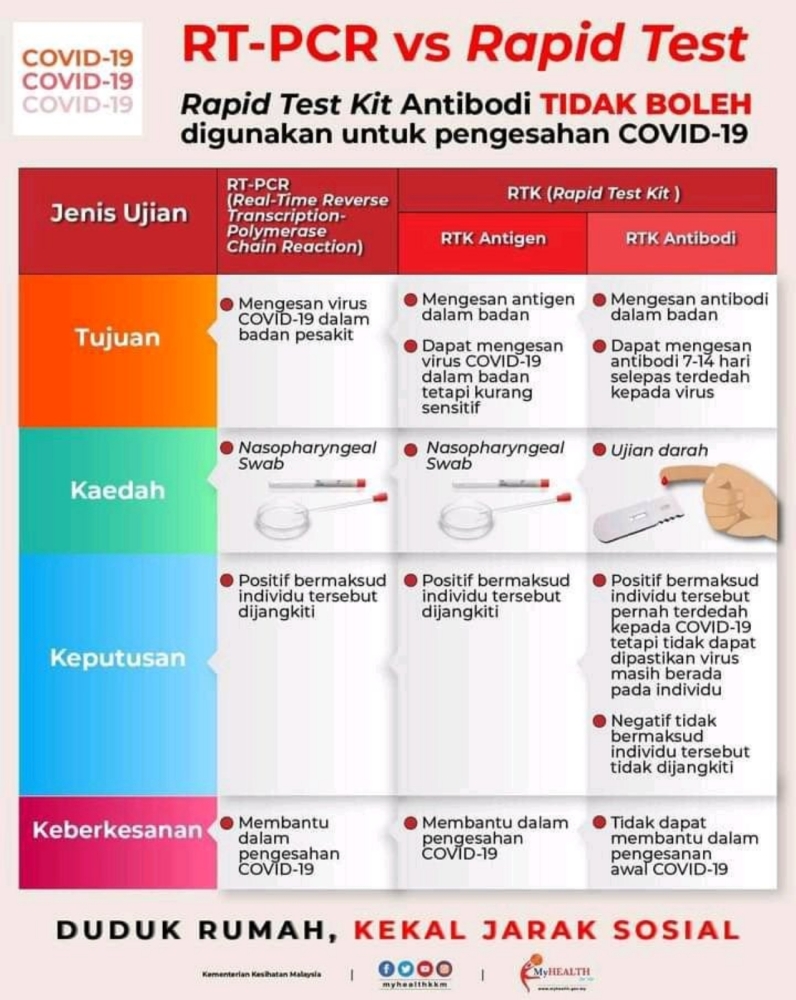

Difference between RT-PCR vs RTK

Jan 22, 2021

Sharing the test we have in the market. What is the difference between them?

This infographic from KKM has giving us clear information.

Stay Safe and Stay Healthy Everyone!

Covid-19 Situation as of 20th January 2021

Jan 20, 2021

Sharing a link to see the whole country situation of Covid-19 by click the link below:

https://covid19.place/?lang=en-US

Stay Safe and Stay Healthy!

5S Series - Sustain

Jan 20, 2021

Today we come to the last series of 5S, which is Sustain.

Sustain is the most difficult section but without sustaining the activities of 1 to 4 of the S series, your effort will be wasted.

Management Support is important

Without commitment from managers, the 5S processes won’t last long. Supervisors and managers should be involved in auditing the 5S work processes, and getting feedback from workers. They also need to provide the tools, training, and time for workers to get their jobs done right.

Department tours has to be done properly

Bringing teams from one department to visit other departments will help familiarize the entire workforce with the processes of your facility. This type of “cross auditing” helps to spread good ideas, and inspires people to come up with new ways to improve the 5S implementation.

Updated training

As time passes, there may be changes in your workplace, such as new equipment, new products, or new work rules. When this happens, revise your 5S work standards to accommodate those changes, and provide training on the new standards.

Progress audits

The standards that are created in the 5S program should provide specific and measurable goals. Checking on those goals with a periodic audit can provide important information and guidance. Where is 5S working well? Where are teams falling behind?

Performance evaluations

Once you know your goals are reasonable, make performance part of each employee evaluation. When teams and individuals perform well, celebrate it, and post overall results so each team can see how they compare to the rest of the facility.

Hope with this last series of the 5S, you able to implement successfully in your process or offices. 5S can help to improve your work area situation to better and better each time. Helping you to save cost in your daily operation as well.

Till then keep on 5S practices all time!

Stay Safe and Stay Healthy!

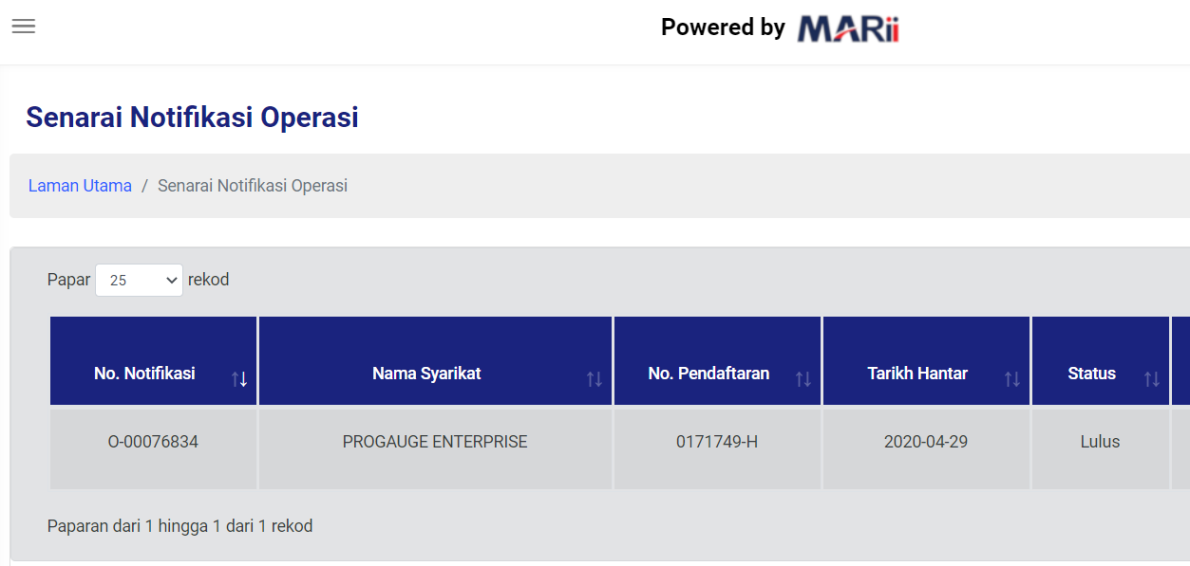

CIMS - Approval for Operation - Progauge Enterprise

Jan 16, 2021

If you require us to visit you at your facilities to take your equipment for operation, we shall follow strictly your facilities SOP.

Do contact us for any of the calibration matters.

Till then Stay Safe and Stay Healthy.

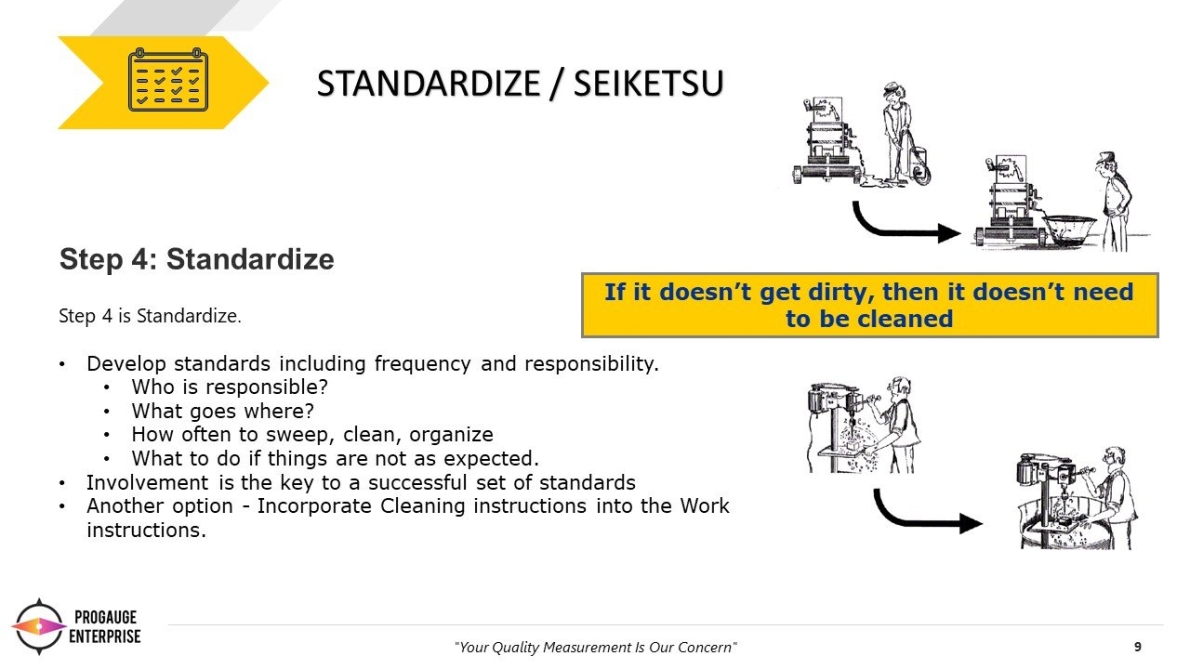

5S Series - Standardize

Jan 15, 2021

We have cover the three steps of 5S cover the basics of clearing, organizing, and cleaning a work space; on their own, those steps will provide short-term benefits. The fourth step is as well important we name it as Standardize, or “seiketsu,” which simply means standardization.

By writing down what is being done, where, and by whom, you can incorporate the new practices into normal work procedure. This paves the way for long-term change.

Record down the decisions that you make in your 5S program will help ensure that your work doesn’t just disappear. If you made a 5S map in the Set In Order step, that map can be part of your new standard for the area. In the same way, the process that you use for red-tagging items can be written down and included in the standards.

Writing out your decisions doesn’t mean you can’t change your mind, though. The purpose of 5S is to make your workplace better, not to make it unchangeable. You are writing the standards for your facility, and you can change them to fit new information or new business needs.

Below are some tools for Standardizing that you may use at your work practices,

This communication is a key part of the Standardize step. Common tools for this process include:

- 5S checklists – Listing the individual steps of a process makes it easy for workers to follow that process completely. It also provides a simple auditing tool to check progress later on.

- Job cycle charts – Identify each task to be performed in a work area, and decide on a schedule or frequency for each of those tasks. Then, assign responsibility to a particular worker (or job duty). The resulting chart can be posted visibly to resolve questions and promote accountability.

- Procedure labels and signs – Provide operating instructions, cleaning steps, and preventative maintenance procedures right where that information will be needed.

5S able to improve your facilities and improve working environment.

Progauge Operation on MCO

Jan 13, 2021

We will follow your regulation if you require us to visit your facilities to get equipment from you.

Do contact us and make arrangement with us for calibration matters.

Till then Stay Safe and Stay Healthy.

Prime Minister Special Announcement - 11 Jan 2021

Jan 12, 2021

PKPB to be implemented on 6 States - Pahang, Perak, Negeri Sembilan, Kedah, Terengganu and Kelantan from January 13 ~ January 26, 2021.

Stay Safe and Stay Healthy.

https://www.facebook.com/LITEdotmy/videos/1041913572966374

5S Series - Shine

Jan 6, 2021

Shine moves far beyond than just pushing a broom around every now and then. It involves regular cleaning of every part of the work area — often a daily wipe-down, and a more thorough cleaning each week.

Importantly, the Shine step is not meant to be a job for the maintenance or janitorial staff.

Each worker should clean their own work area, and the equipment they use.

This approach has several benefits:

- Workers who are familiar with the area will quickly notice any problems that arise

- Hazards or difficult situations will be understood and accounted for

- Items that are out of place or missing will be recognized

- Workers will tend to keep their own workspaces cleaner during normal operations

But for 5S to give the best results, each worker should take personal responsibility for their own working space.

Shine can be as Preventative Maintenance

Keeping work areas clean will have many advantages. One important advantage is that it’s easy to spot leaks, cracks, or misalignments.

If the people keeping the area clean are the same people who work there regularly, they will be quick to recognize any of these problems.

Leaving those problems unnoticed and unresolved could result in equipment failure, safety hazards, and loss of productivity.

With the constant cleaning and inspections used in the Shine step of 5S, the system can feed into a preventative maintenance program.

This way, 5S can extend the working life of equipment and help reduce emergency downtime.

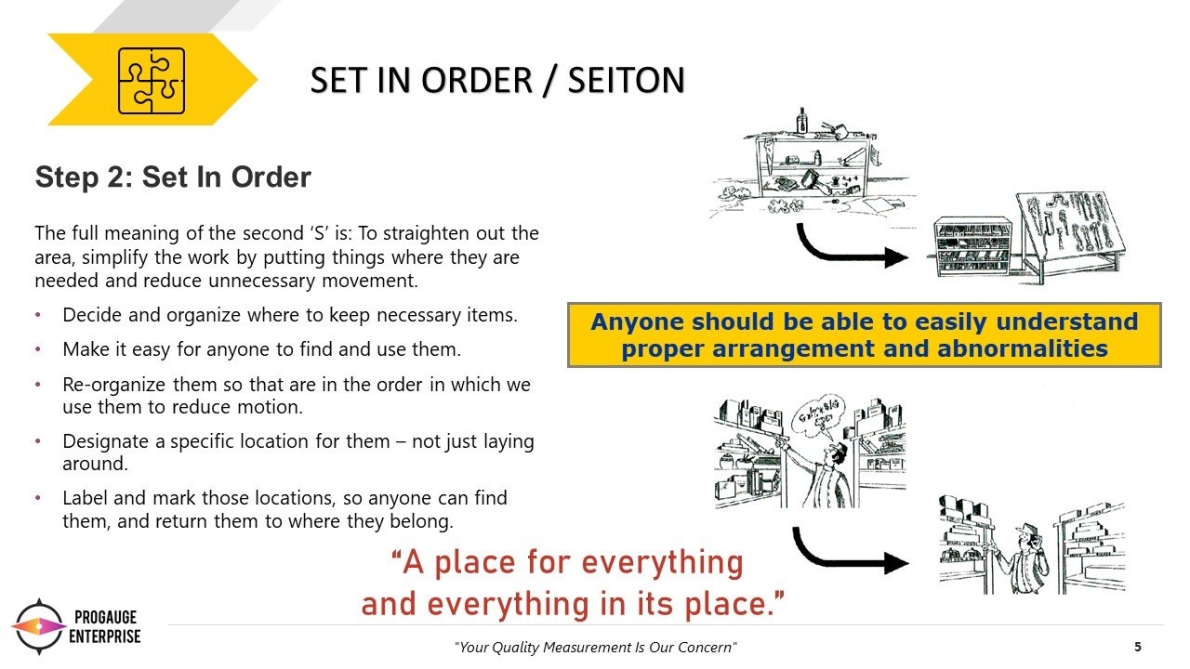

5S Series - Set In Order

Jan 5, 2021

The goal here is to organize the work area. Each item has it's own place and should be easy to find, use, and return: a place for everything, and everything in its place. Tools that are used frequently should be stored near the place they are used.

Spare equipment, supplies, and other tools that are used less often can be kept in a central location, where multiple teams can share them.

Items that are typically used together (such as drills and drill bits) should be stored near each other.

Each of these decisions will make sense on its own, but it may become difficult to keep track of everything.

It may be helpful to create a 5S map as part of this process.

A 5S map is a diagram or floor plan that provides an overview of a work area, process, or station. It provides a visual reference to show where the tools, supplies, workers, and travel paths are, and how they relate to each other. A good map may also include a description of the work that happens in the area shown.

No matter which approach is used to create it, the resulting 5S map should be kept as a training tool, used for reference in later steps of 5S, and updated over time as the work area changes.

Once storage locations are assigned, each storage area should be labeled. Label the outside of cabinet doors to help workers quickly identify what’s inside each one. Then, label any interior shelves to show where different supplies belong. The same ideas extend to rack labels, bins, and other storage systems.

Organization can extend to the floor, too. Work areas, movement lanes, and storage for supplies and finished products can all be marked with floor marking tape.

Hope above will help you and your organization have knowledge and implement 5S.

5S able to improve your facilities and improve working environment.

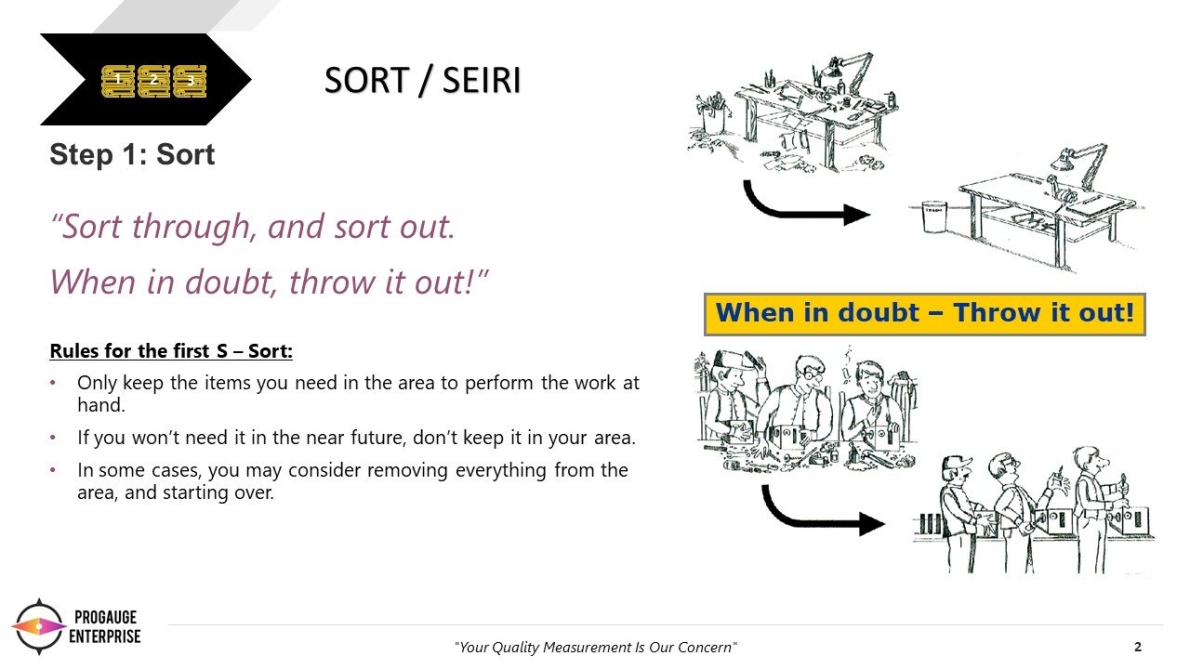

5S Series - Sort

Jan 4, 2021

Let's continue with education with this time is 5S. Today posting we touch in first of the 5S which is Sort.

For this step, take a close look at the items, tools, and materials in a work area. Items that are necessary or useful for the work being done in that space should be kept there. Everything else should be removed.

Some of those removed items will need to be thrown away or recycled. Other items might belong to another work process or location; they should be returned to their “homes.” However, you might find some items that you aren’t sure about.

Red-Tagging Unknown Items

If you find an item that you can’t identify, or that has uncertain ownership, it’s time to use a red tag. “Red-Tagging” temporarily attaches a highly-visible tag to the item, which notes where it was found and when. Then, red-tagged items from all work areas are collected in a single location: a “lost and found” for tools, materials, and equipment.

So let's begin this very 1st step of 5S - Sorting!

Remember clearing out unnecessary materials in step 1 (Sort) will provide the space needed to organize the important items in step 2 (Set In Order).

Then, once the work space is de-cluttered and organized, dirt and grime can be removed in step 3 (Shine).

These changes to workers’ job duties and work environment should be reflected in updated procedures through step 4 (Standardize).

Finally, those new procedures won’t amount to much unless responsibility is assigned and progress is tracked — as required for step 5 (Sustain). And with responsibility and tracking, workers will continue to apply the steps, returning to step 1.

Merry Christmas and Happy New Year

Dec 24, 2020

Christmas - 24th Dec ~ 25th Dec

New Year - 31st Dec and 1st Jan 2021.

Progauge Enterprise would like to wish you and your family

Merry Christmas and Happy New Year!

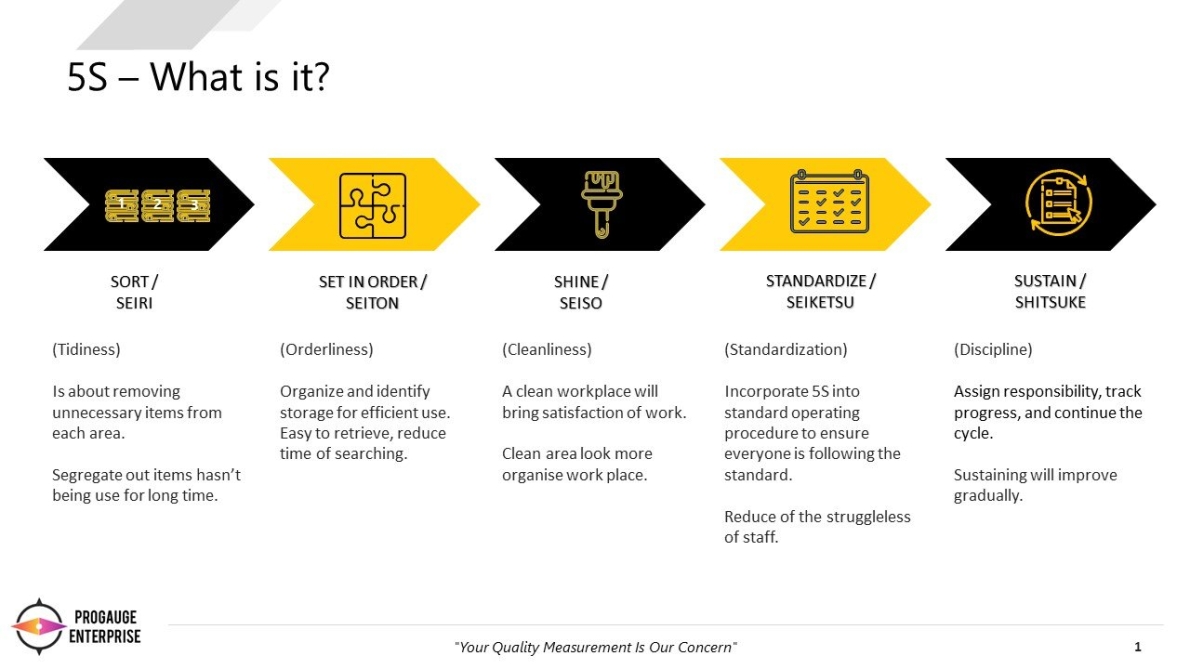

5S - What is it? - Series

Dec 22, 2020

Information of 5S can be ontain from website easily. There are more of 5S details in the website. Here Progauge will share in the simplest term of 5S that you able to learn.

We will do it in series positing. Do check our news platform time to time.

Here is what is the 5S that we explaining. Don't worry that we will go in details each of the ''S'' in series of our posting.

Enjoy!

2021- Progauge Enterprise Working Calendar

Dec 20, 2020

You may download our Working Calendar and keep it as your reference.

https://cdn1.npcdn.net/userfiles/22253/download/1608433603_b518ad3e20f4a7d9e96ab633d3141dd7/2021_-_Progauge_Enterprise_Working_Calendar.pdf