Latest News

Covid-19 Negeri Sembilan - 11th December 2020

Dec 11, 2020

.jpg)

Always Wear Mask, Wash Hand and Keep physical distancing all time.

SWOT analysis for Small Businesses is Important

Dec 11, 2020

A SWOT analysis could help you and your small business operates in smart, informed or cost saving business decisions.

Understanding your company’s position within your market or industry and knowing how and where you can grow is critical for any small business owner.

Strategically develop your company rather than wasting your efforts trying to expand into a market that doesn’t align with your business or being overrun by surprise competitor.

What is SWOT Analysis?

SWOT – which stands for ''strengths, weaknesses, opportunities and threats'' – is a type of analysis that helps you develop your business strategy by comparing internal factors (strengths and weaknesses) against external factors (opportunities and threats).

A SWOT analysis has four quadrants:

|

STRENGTHS Strengths are internal, positive attributes of your company. These are things that are within your control. (Internal company factors) |

WEAKNESSES Weaknesses are negative factors that detract from your strengths. These are things that you might need to improve on to be competitive. (Internal company factors) |

|

OPPORTUNITIES Opportunities are external factors in your business environment that are likely to contribute to your success. (Factors external to the company) |

THREATS Threats are external factors that you have no control over. You may want to consider putting in place contingency plans for dealing them if they occur. (Factors external to the company) |

A SWOT analysis is a good tool for general business strategizing and serves as a starting point for team discussions. When conducted thoroughly, a SWOT analysis can uncover a much more information and can be useful in a number of situations for improvement of your company.

Let’s breakdown the SWOT Analysis Process.

We know that SWOT stands for Strengths, Weaknesses, Opportunities, and Threats – Let’s take a look at each element individually, each of the quadrants has few examples on how to established each of the quadrants.

|

S Strengths |

W Weakness |

O Opportunities |

T Threats |

|

|

|

|

One of the most important parts of your SWOT analysis is using it to identify new strategies and goals for your business. For example, you can:

- Create a plan to build up your strengths even more.

- List ways you can work on building up your weaknesses.

- Set SMART goals for each of the opportunities you identified.

- Devise a plan to use your strengths to decrease the threats you identified.

Then, look for ways to combine data from different quadrants in even more ways:

- Explore how you can combine your strengths and opportunities to develop new strategies.

- Try combining strengths and threats to identify threats you can eliminate.

- Look at your weaknesses and opportunities to create a list of areas ready for improvement.

- Make a list of areas to avoid that fall under weaknesses and threats.

Once you understand how to establish your SWOT data and find ways to use it strategically, the SWOT analysis will be a tool that you can use over and over in your business to improve further strategies accordingly to current.

Progauge, will share its own SWOT analysis in series, which we have brainstorms over our yearly business meeting. Hope with this sharing you able to have some lead to gets your own SWOT analysis up and running in your company and improve tremendously.

Covid-19 Negeri Sembilan - 10th December 2020

Dec 10, 2020

This is today situation of Covid-19 in this State.

Total of 67 positive case detected.

Wear Mask, Wash Hand and Keep physical distancing all time.

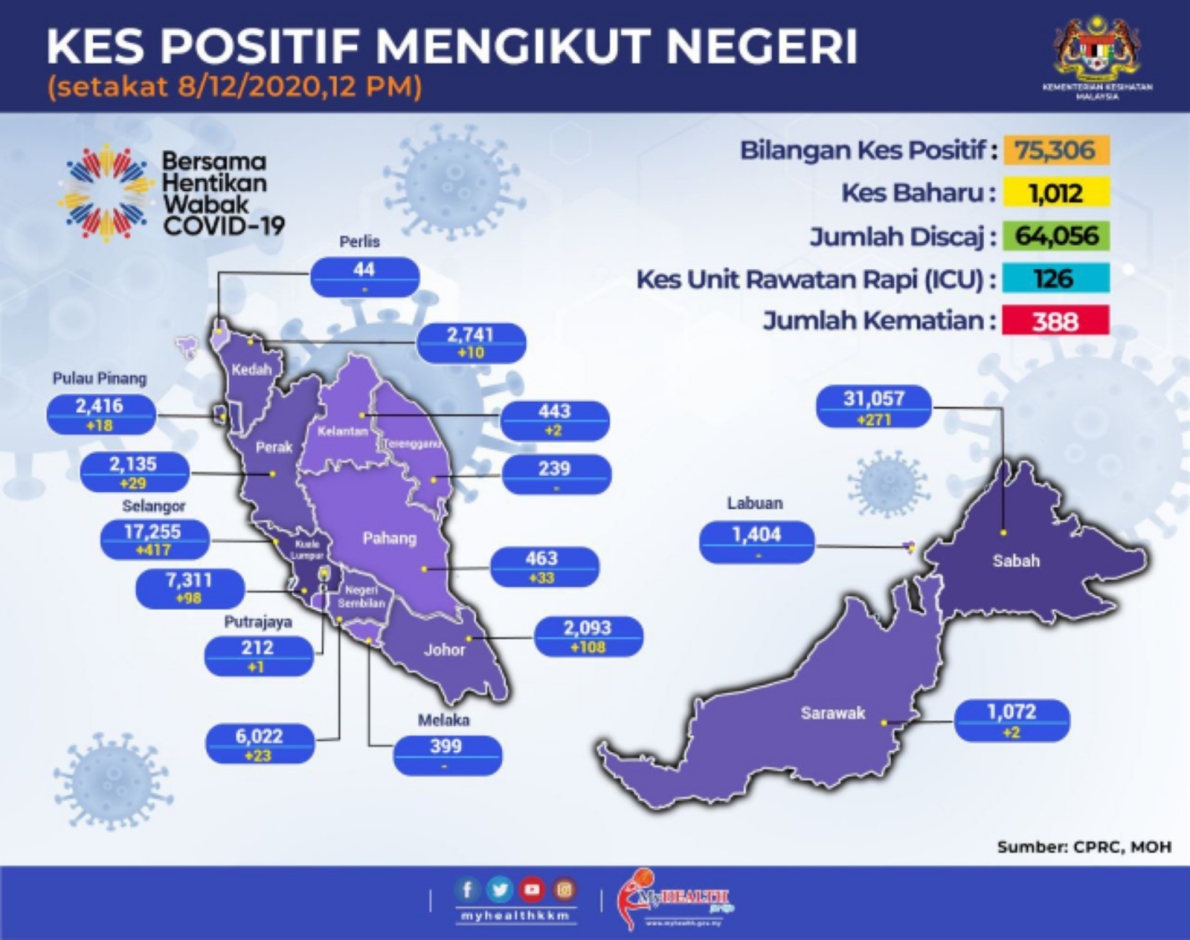

Covid-19 - Negeri Sembilan 8th December 2020

Dec 8, 2020

Covid-19 of Negeri Sembilan state for today has drop. Total of positive cases detected in this state recorded 23.

Always Wear Mask, Wash Hand and Keep physical distancing all time.

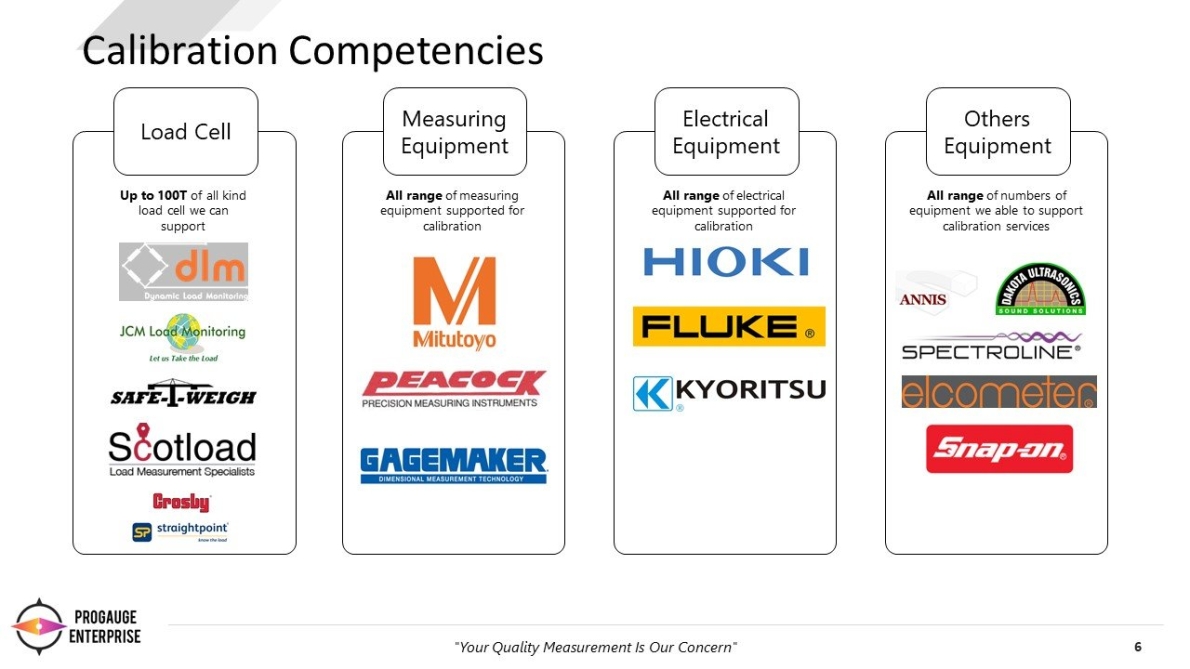

Progauge Calibration Competencies

Dec 8, 2020

Do contact us for calibration matters and talk to us if you find yourself struggle with ''Do I need to calibration this?''

Call us or Whatapps us @ +6011-635 00 321

Drop us email @ progauge@gmail.com

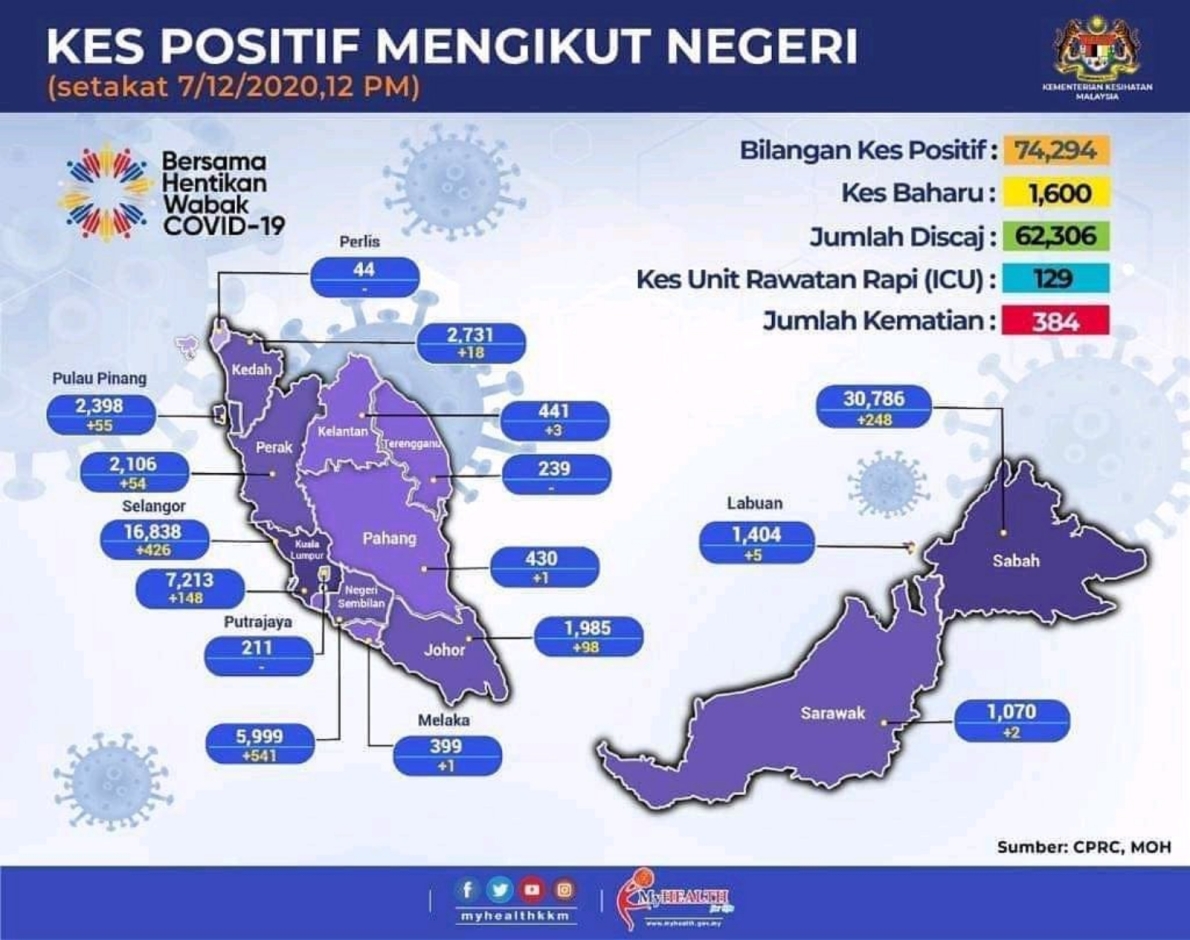

Covid-19 - Negeri Sembilan 7th Dec 2020

Dec 7, 2020

Being as company established in Negeri Sembilan state. We play our role and responsible for the social in this state.

We has being monitored since beginning of the Covid-19 arrive in Malaysia on month of March 2020. Since then we are following Government SOP strickly till today.

Today our state found positive case and rank as No. 1 in the whole country with numbers of people has contacted with Covid-19.

Rest assure that we have work closely with our associates business partner and implement the SOP regulations obtained from Government. Up to now our associates business hasn't been affected to close. Operation is still ongoing.

Do contact us for calibration matters by email to progauge@gmail.com and or alternatively contact us thru WhatsApp at this number +6011-6350 0321.

Progauge Enterprise wish you and your family in great health and stay Safe.

Wear Mask, Wash Hand and Physical Distancing all time.

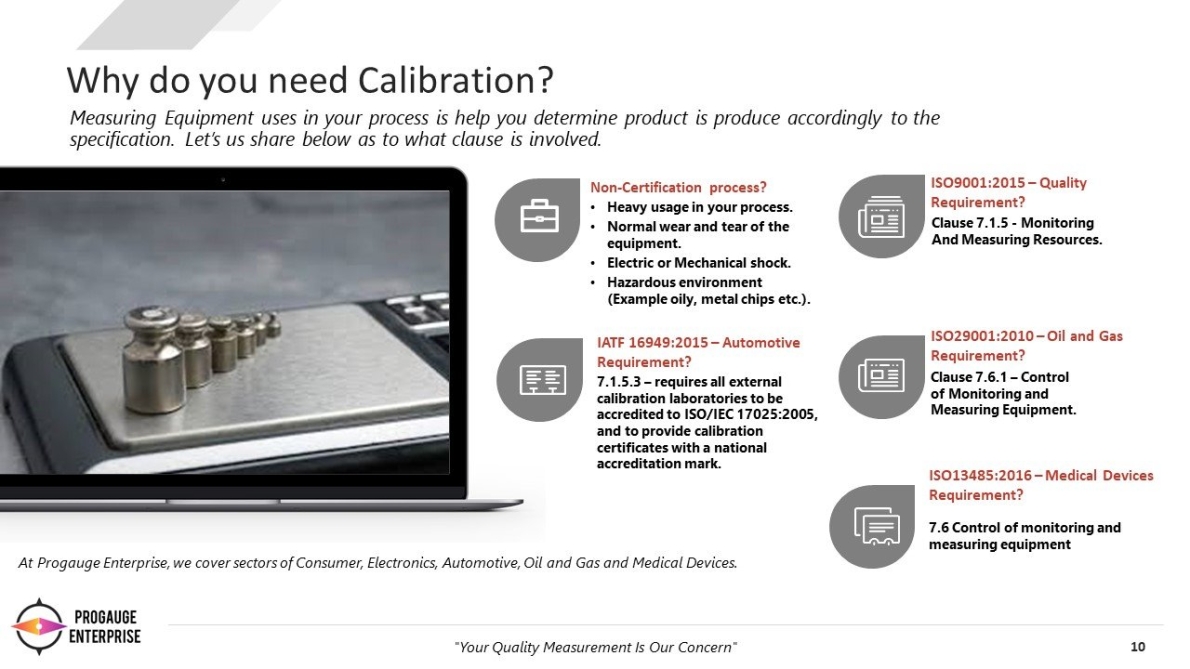

Why Calibration is important and needed?

Dec 7, 2020

Why calibration is important and needed?

- Is requirement of your Quality System.

- Is about accuracy of all measuring devices.

- Equipment accuracy will degrade over time.

- Typically caused by normal wear and tear. However, changes in accuracy can also be caused by electric or mechanical shock or a hazardous manufacturing environment (e.x., oils, metal chips etc.).

- Depending on the type of instrument and the environment in which it is being used, it may degrade very quickly or over a long period of time.

- The improtant mindful of calibration is that it's improves the accuracy of the measuring device. Accurate measuring devices improve product quality.

When should you calibrate your measuring device?

- According to the recommendation of the manufacturer.

- After any mechanical or electrical shock.

- Periodically (annually, quarterly, monthly)

- Requirement of your quality system.

- The hidden costs and risks with un-calibrated measuring device could be much higher than the cost of calibration. Therefore, it is recommended that the measuring instruments are calibrated regularly by a reputable company to ensure that errors associated with the measurements are in the acceptable range.

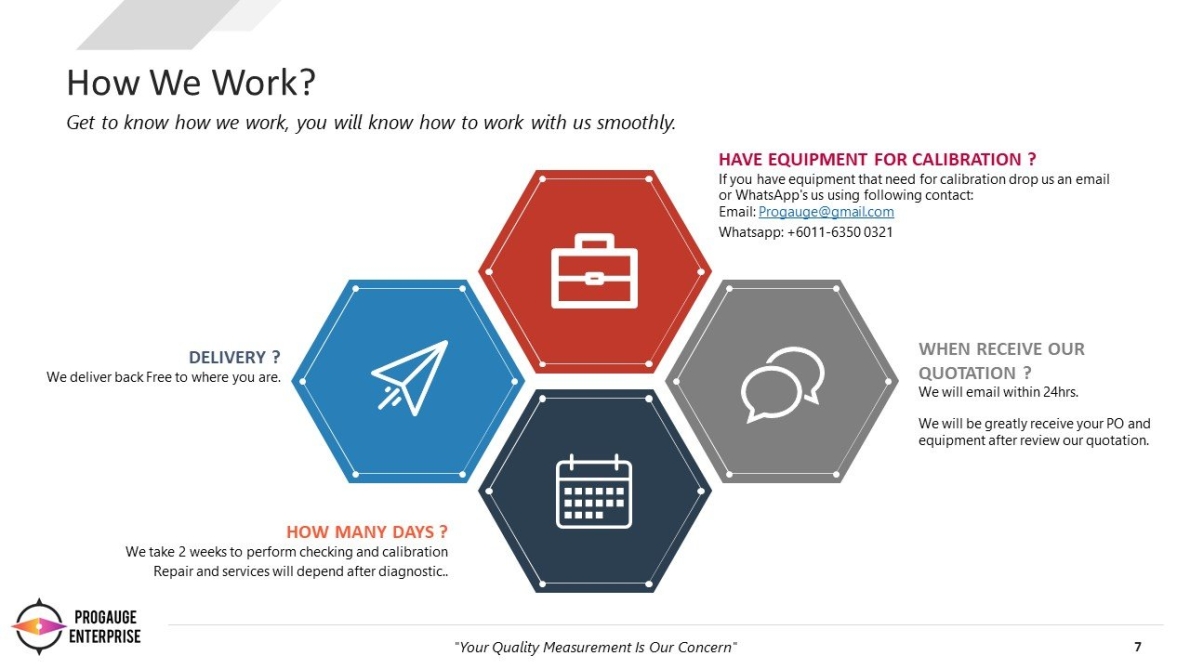

How We Work?

Dec 5, 2020

Here is Infographic, were is as simple as 4 steps that you can refer.

Do contact us!

Waste No. 7 - Waste of Transportation

Dec 2, 2020

Waste No. 7 - Waste of Transportation

What it is?

- Transport a lot from one process to one process taking long period of time is a waste of transportation.

- A poor layout of process from start to finishing can also lead to movement of lot and people taking long period of time.

- Large size of batches can also contribute waste of transportation.

- Multiple storage area can also cause waste of transportation.

- Multiple storage of tools and equipment causes waste of transport.

- Create value stream and make the flow of the process at the pull of customers.

- Creating value stream, created process that production line contain value adding process rather a functional process.

- Reducing the space of the process to make the process in short and fast output.

- Improving factory layout through the use of value stream mapping and process mapping can give huge savings in time and money.

- Waste of overproduction can also lead to waste of transportation. Over production lot need to travel more frequent.

By reducing Transportation you will improve the productivity and process efficiency and further reducing operating costs and eventually increase operating profit margin.

If you have more idea why not drops us in comment - Thanks!

Waste No. 6 - Waste of Defects

Dec 1, 2020

7 Waste of Lean Manufacturing series and today we talk about

Waste No. 6 - Waste of Defects

What it is?

- Waste of correction that includes additional work implemented into the product.

- Cause by unclear working instructions or procedure.

- Such as unnecessarily of tolerance such as too tight that beyond machine capability to produce.

- Inadequate training given to the operator.

- Incapable of the machines.

How you over come it?

- Poka Yoke can help in reducing or eliminating error produce by human.

- Process that can be replace using automation can further assist operator in producing consistent product.

- Regular OJT (On Job Training), this is to instill operator knowledge of the work and upgrading skills.

- Regular review the design of the product with value engineering or value analysis to identify opportunity of improvement.

- Too many of over processing, Off-cut product can also lead to defects pile up and potential create mix of bad and good.

Hope above simple sharing can give you some of pointers to help your process to overcome the waste No.6 - Defects in Lean manufacturing.

By reducing defects you will improve the productivity and process efficiency and further reducing operating costs and eventually increase operating profit margin.

If you have more idea why not drops us in comment - Thanks!

Waste No. 5 - Overprocessing

Nov 30, 2020

Waste No. 5 - Waste of Over processing

What it is?

- Putting more effort, value into the product than it's cost valued by customer.

- Such as unnecessarily of tolerance such as too tight, over clean or over polishing beyond the requirement.

- No standardization of best technique can lead to over processing.

- Unclear specification of the product.

- Unclear quality standard requirement.

- Again 5S can be use in reducing or eliminating over processing.

- Implement SOP with proper pictures on how the processing work, this is visual guided standard.

- Another visual guided is by video, can be use to guide operator to work accordingly.

- Regular OJT (On Job Training), this is to instill operator knowledge of the work and upgrading skills.

- Regular review the design of the product with value engineering or value analysis to identify opportunity of improvement.

By reducing waiting you will improve the productivity of your workers and reduce your operating costs and eventually increase operating profit margin.

If you have more idea why not drops us in comment - Thanks!

Waste No. 4 - Waste due to Waiting too long

Nov 29, 2020

Waste No. 4 - Waste of Waiting

What it is?

- It is the act of doing nothing by stood there for long period of time waiting for a previous step in the process.

- Operator waiting for the product complete while the machine in running.

- Waiting was created by poor machine maintenance.

- Waiting existed by long changeover.

- Waiting created by unreliable process or many defects.

- Improving machine reliability and quality by using Total Productive Maintenance (TPM) and quality tools.

- Reducing overproduction and inventory to minimize transport and movement between and within cells.

- Develop a standard operating procedure to ensure the process has standardize operating and clear instruction for operation.

- Use visual methods of planning to give details of planning work.

- Regular daily group meetings to ensure that everyone is clear what is required for the day.

By reducing waiting you will improve the productivity of your workers and reduce your operating costs and eventually increase operating profit margin.

If you have more idea why not drops us in comment - Thanks!

Waste No. 3 - Waste of Motion

Nov 28, 2020

Today we continue with the 7 Waste of Lean Manufacturing series.

Waste No. 3 - Waste of Motion

What it is?

- A process that has step that is not value adding, moving is not necessarily working existed.

- Too many motions or steps may cause by poor layout of the process.

- Poor design of process of transferring from one process to another process.

- Poor workplace organization.

- Large batch sizes.

How you over come it?

- Look back at each of your process and look for any job that burden the operator, this should be minimize.

- Implement 5S into each of your process to look for any struggle area and improve using 5S methodology.

- Develop a standard operating procedure to ensure the process has standardize operating.

- Implement Single minute exchange tool (SMED) to remove wasteful motion in steps.

- Regular check the processes for any new waste created.

This may help your process to overcome waste of motion, the waste No.3 in Lean manufacturing.

If you have more idea why not drops us in comment - Thanks!

Waste No. 2 - Excessive of Inventory

Nov 27, 2020

Waste No. 2 - Excessive of Inventory

What it is?

- Inventory consists of your excess of Raw Material, excess of Work in Progress (WIP), Finished Goods.

- Unnecessary inventory stock up before and after in a process.

- Lack of balance in work flow.

- Failure to practices first in and first out.

- Incapable processes, long changeover time and didn't follow procedure.

How you over come it?

- Setup flow of product at the pull of customer

- Practice JIT (Just In Time).

- Implement Kanban system, used to help ensure balance the processes and prevent the build up of inventory.

- Re-layout processes to achieve continuously flows.

- Optimize your machine to be efficient and consistent output.

If you have more idea why not drops us in comment.

Sharing is Caring! Thanks!

Progauge Enterprise Company Profile

Nov 26, 2020

https://cdn1.npcdn.net/userfiles/22253/download/1607517594_56ba7492fe29999ffd0cfbd1c4b48de2/Progauge_Enterprise_Company_Profile_20_21.pdf

Thanks!

Waste No. 1 of Lean - Overproduction

Nov 26, 2020

7 Waste of Lean Manufacturing series.

Waste No. 1 - Overproduction

Below is some example of how overproduction can happen in any of manufacturer process. So what overproduction it is?

- Making products in too great a quantity.

- Unreliable processes.

- Unstable schedule.

- Inaccurate of forecast.

- Inaccurate information and not actual demand.

How you over come it?

- Practice JIT (Just In Time)

- Work with supplier to implement Just In time.

- Steam line your process that provide fast output.

- Work with customer on the actual demand of product.

- Optimize your machine to be efficient and consistent output.

This may help your process to overcome overproduction, the waste No.1 in Lean manufacturing.

What is 7 Waste of Lean?

Nov 25, 2020

We have this series on our Facebook section in the month of April this year.

Good sharing of Lean information from us and we share again in our new website.

If your company is practicing 7 waste of lean elimination, you will overcome and excel in this time of Covid-19 pandemics.

What is 7 waste in the Lean?

- Overproduction of goods.

- Inventory of process floor stack up.

- Too many defects.

- Too much of motion involve.

- Waiting time too long.

- Over processing of your goods.

- Transportation takes longer time.

Have these 7 waste of lean exist in your process. Time to use this methodology to eliminate.

Cheers!

1.6 Source of Uncertainty

Nov 25, 2020Previous we have talk about Measurement uncertainty. Today we touch on source of the uncertainty coming from.

The uncertainty of the result of a measurement reflects the lack of knowledge of the value of the measurement.

Here we list out the possible sources of uncertainty:

- Incomplete definitions of the measurand.

- Imperfect realisation of the definition of the measurand.

- Sampling - the sample measured may not represent the defined measurand.

- Inadequate knowledge of the effect of environmental conditions on the measurement procedure.

- Personal bias in reading analogue instrument.

- Instrument resolution or discrimination threshold.

Above is possible can lead to source of uncertainty happen. Reduce above can help to obtain proper measurement.

1.5 Measurement Traceability

Nov 24, 2020Concept of ''traceability of calibration'' simply means that a working instrument shall be calibrated against a reference instrument and the reference instruments shall be calibrated against a more accurate instrument.

Your equipment calibrated by Progauge Enterprise is accrediated to International Standard Laboratories ISO/IEC 17025. Your worry free is taken care by us.

1.4 Measurement Uncertainty

Nov 23, 2020- System - Equipment, Standard Used

- Human - Skill, Experience

- Procedure - Method used

- Environment - Temperature, Humidity

- System Uncertainties

- Random Uncertainties

Usually the confidence probability of not less than 95% for most of the calibration lab but some of the more sophiscated laboratories may quote confidence probability of not less 99%.